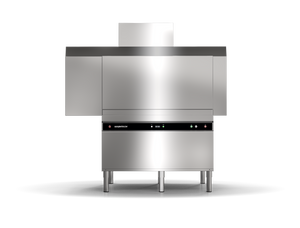

Conveyors

The benchmark for reliability and serviceability.

All Washtech conveyor dishwashers are constructed from heavy-duty stainless steel, and use heavy-duty stainless steel componentry throughout the wash system. The dual-track, heavy-duty stainless steel pawl drive delivers smooth conveyor operation, and the electromechanical control system offers superior reliability and longevity over fully electronic systems.

Our conveyors are designed with serviceability in mind. Wide counterbalanced doors and an open pawl drive architecture provide direct access to the wash chamber, tanks and wash arm cassettes, simplifying cleaning and maintenance procedures. Washtech also offers 24/7 service and support nationwide, and guarantees 15 years of parts availability for all models.

World-class power and water consumption.

Our flagship CDe conveyor models pioneered our integrated heat recovery unit, which condenses steam emissions and recirculates their heat to the incoming water. This reduces power consumption by up to 60%, significantly lowering operating costs. We now offer the heat recovery unit as an option on standard CD models, making it more accessible to more operators.

CDe models also include our innovative multi-stage EcoRinse system, reducing water consumption to 180 litres per hour on CDe120 and CDe180, and just 120 litres per hour on CDe240. This equates to 0.5 litres per rack at full speed, making CDe240 4x more efficient than CD120, and approximately 5x more efficient than typical undercounter or passthrough dishwashers.

A complete system solution.

Washtech offers a broad range of built-to-order options that are engineered to deliver great wash results in various scenarios. Options such as custom rack paths, rack slides and the central pawl drive can optimise for oversized kitchen items. Cold injection pre-wash prevents excessive heat in the pre-wash zone for sites with high ambient temperature.

When specifying a complete conveyor system, the right accessories are as important as the right dishwasher. Washtech offers a broad range of system accessories designed to maximise the efficiency of the overall system, by optimising loading and unloading procedures, maximising utilisation of available space, automating the drying process and more.